Collaborative Design of Prefabricated Façade Systems

About

Codefa nominated to Design Preis Schweiz!

How we work: Digital Craftsmanship

To enhance creativity and design freedom among architects, we stream our research investigations into three main directions: custom parametric modelling instruments, flexible robotic fabrication and most importantly a collaborative design process between various stakeholders. The digital design and fabrication tools are developed in parallel and are informed with technical limitations and material properties of wood. As such, this solution brings a new value to the industrial setup, a digital craftsmanship, where the creative needs and technical feasibility meet a stable ground forming continuous design-to-fabrication process.

Digital Tools

In order to provide more transparency, shorten the design–to–production process and provide creative freedom for architects, we develop a set of custom parametric tools of varied functions. These are playful instruments that boost architects’ creativity, help them to visualize their ideas, estimate costs as well as rationalization tools for engineers to facilitate the facade planning phase and ensure continuous digital workflow.

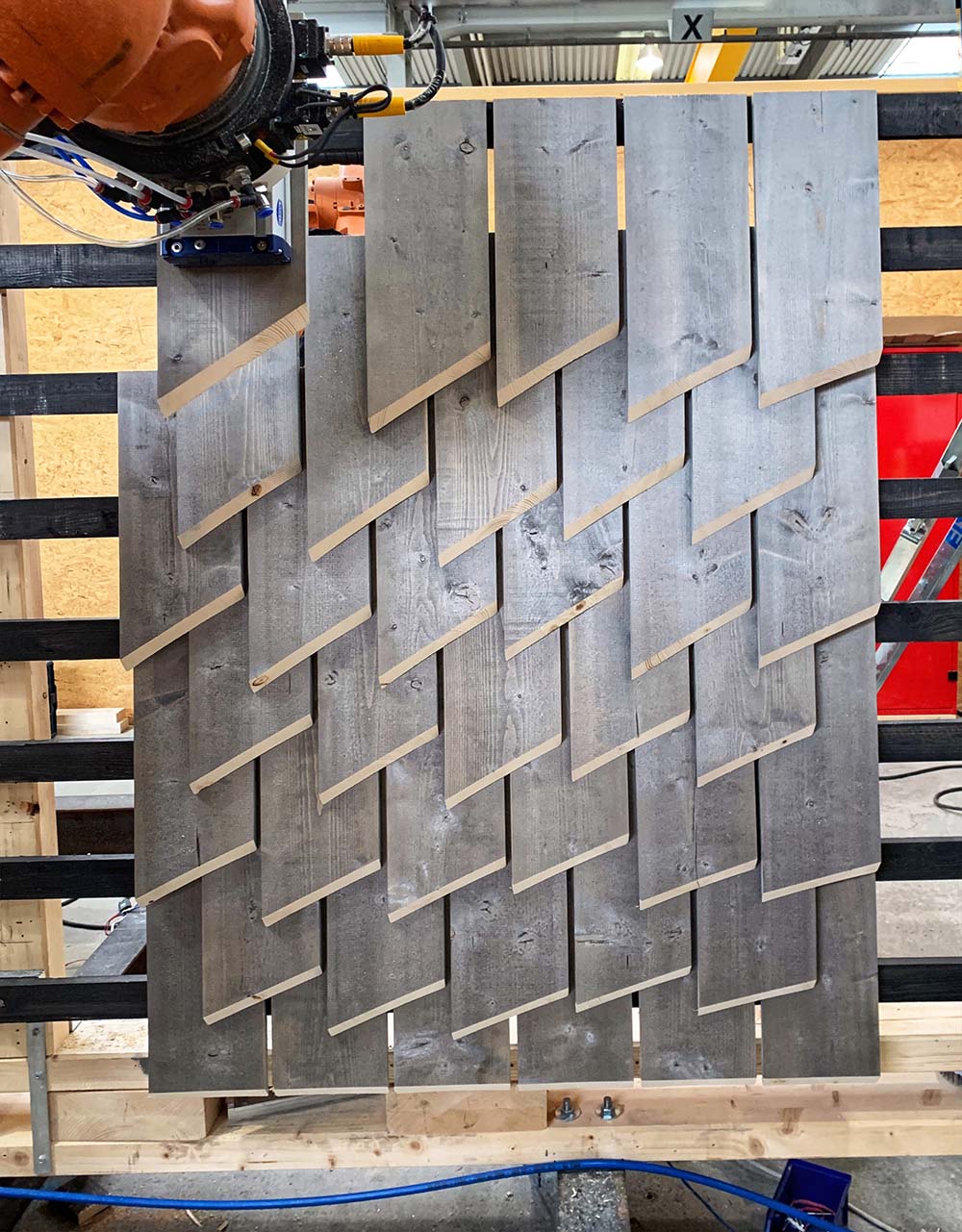

Robotic Fabrication

We analyse and improve existing industrial production processes of ERNE AG Holzbau as well as establish new automated production methods to support architects during the creation of their individual ideas. Through collaborative work between researchers and ERNE’s engineers, we established innovative 2-robot fabrication processes for complex façade assembly as well as a set of individual supporting production processes.

Collaborative Design

Understanding architects’ expectations towards facade systems are crucial in our investigations. We ground our research on the concept of collaborative customization, in which the needs of the customers inform the manufacturing process. We explore different modes of exchange between architects and the construction company and adjust accordingly the offer of the industrial partner.

Process

to design and fabricate unique facade systems

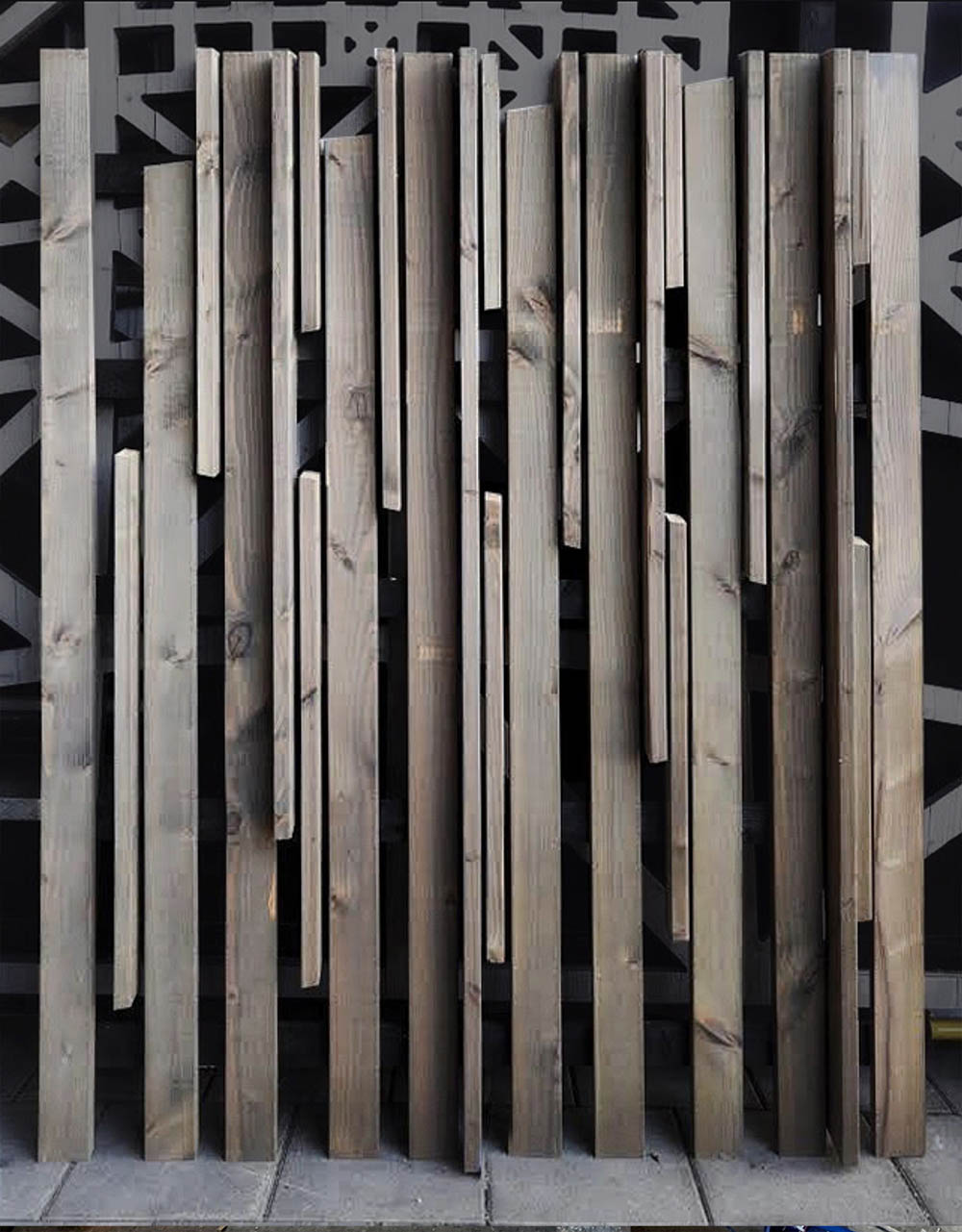

Wood facades: Learning from the past

Wooden facades have a long history in Switzerland. Their form and aesthetics steam from centuries of trials and errors, which led to optimized systems regarding available resources, production feasibility and performance in the local climate. In our research we are learning from the old masters. Together with carpenters, wood engineers, robotic specialists and architects we are looking for the new interpretations of historic wood façades – shingles, board-on-board and beam-based facades. With the help of new design and production technologies we creatively expand its aesthetic expression, while keeping original logic and performance.

Shingles

Beam facades

Mixed facades

Demonstrator: Office Saig

The demonstrator of the project, four outstanding facades on the modular office building in Stein, Switzerland was accomplished in November 2020. The front and back beam-based facades create architectural frame for the shingle and multi-layered facades on the sides. These 3 types not only reinterpret the most common Swiss traditional façade solutions, but also explore to the maximum the constructed fabrication toolbox, as each type represent different fabrication logic and challenges.

Working with architects: a collaborative process

One of our main goals is providing architects the possibility to customize the prefabricated façade systems through collaborative design process with the manufacturer. Early interdisciplinary exchange is crucial to create outstanding façade systems within a reasonable price range. That is why, each project starts with a workshop between manufacturer, engineers and architects, where digital design tool is adjusted to the vision of our partners. At the same time, the tool playfully expands design variety, ensures that the developed system is within the available production possibilities and evaluates its price. In the next step, we build the mockup with the robotic infrastructure of ERNE AG Holzbau to further improve the design until it meets architects’ expectations.

Online questionnaire

If you’re an architect, you’re very welcome to support our research with your knowledge! Please fill out the online questionnaire. We want to know your experience and expectations towards working with the prefabricated facade systems, dedicated design tools, importance of fabrication methods and collaboration with the construction company.

Outreach

expert talk @ Herzog & de Meuron Digital Technologies Group

12.2020, Basel

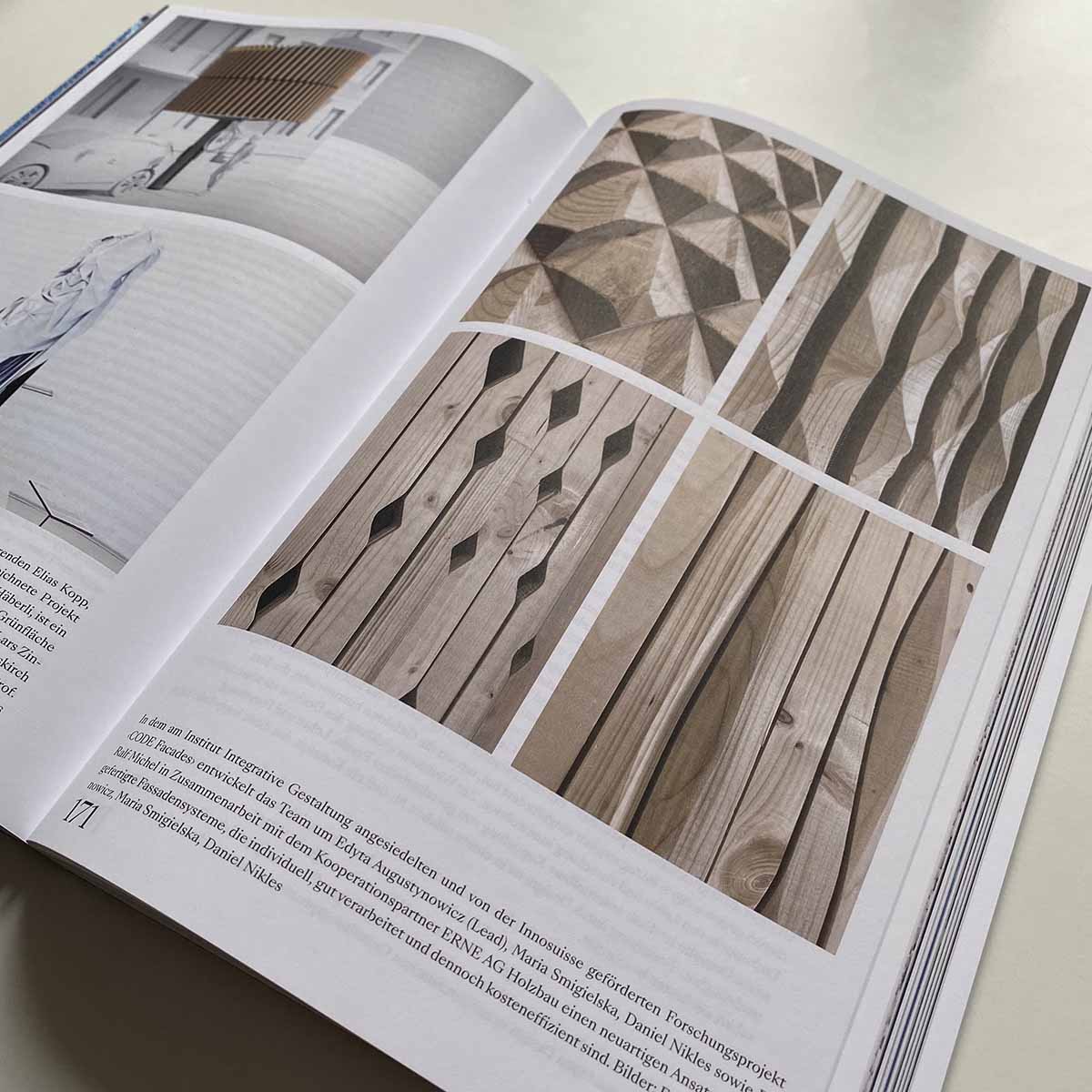

mention in the article in the FHNW publication

2020, Basel

Related projects

Team

The project was initiated by Edyta Augustynowicz in 2018 as a joined research between University of Applied Sciences and Arts Northwestern Switzerland, FHNW and ERNE AG Holzbau. Our team is highly interdisciplinary and consists of researchers, experienced computational designers,

Edyta Augustynowicz

Maria Smigielska

Daniel Nikles

Thomas Wehrle

Prof. Heinz Wagner

Dr. Ralf Michel

Project Partners

Location

HGK | FHNW – Basel

Institute Integrative Design | Master Studio Design

Freilager Platz 1, 4002 Basel, Switzerland

team@codefa.ch